Calculating the rotational speed of an electric motor is essential for matching the motor to its driven equipment. The operational RPM (Revolutions Per Minute) defines the performance characteristics of the machine. For Santroll, providing clear technical parameters for their electric motors allows for precise integration into various systems. The primary method for determining speed relies on the motor’s fundamental design and power supply.

Synchronous Speed Calculation for AC Motors

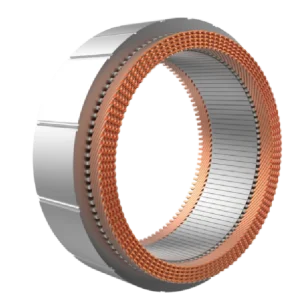

The theoretical speed of an AC induction motor, known as its synchronous speed, is determined by the frequency of the power supply and the number of magnetic poles in the stator. The formula is: Synchronous RPM = (120 × Frequency) / Number of Poles. For a standard 60 Hz power supply, a 4-pole electric motor has a synchronous speed of 1800 RPM. This calculation provides the speed of the motor’s rotating magnetic field, a key design parameter for all Santroll AC electric motors.

Factoring in Slip for Actual Operating Speed

In practice, an induction electric motor always operates slightly slower than its synchronous speed. This difference is called “slip,” which is necessary for the motor to produce torque. The actual RPM is found by applying the motor’s slip percentage, typically provided on the nameplate. For example, an electric motor with a synchronous speed of 1800 RPM and a 3% slip will run at approximately 1746 RPM under full load. This value represents the real-world operating speed.

Measuring RPM with Instrumentation

When a motor is already in operation, or nameplate data is unavailable, direct measurement is required. Technicians use

handheld digital tachometers, which can be optical or contact-based, to read the shaft speed directly. Alternatively, stroboscopes can be used to visually freeze the rotation of a marked shaft for measurement. These methods provide empirical data for the RPM of installed electric motors, useful for performance validation and diagnostic purposes.

Understanding these calculation and measurement techniques ensures correct application and system compatibility. Santroll‘s technical documentation for its electric motors includes critical data like pole count and expected slip, facilitating accurate speed prediction. This knowledge supports proper system design, helping to avoid issues related to under-speed or over-speed in the driven machinery.