As manufacturing systems evolve through the integration of AIoT, cloud computing, and automation, surface mount technology (SMT) must address increasing demands for efficiency and flexibility. Central to this transformation are reliable SMT assembly storage solutions and well-integrated systems provided by established SMT equipment manufacturers.

Storage Solutions as a Strategic Component

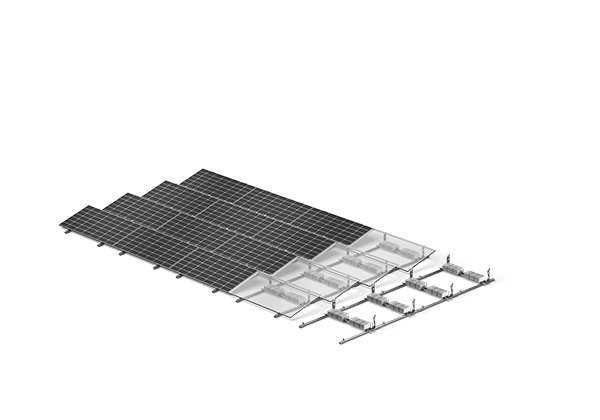

Efficient SMT assembly storage solutions have become critical to the overall performance of electronic manufacturing lines. By automating the handling, tracking, and retrieval of components, these systems reduce idle time and ensure accurate material flow. PassionIOT has developed warehousing systems that support high-speed operations, high precision, and low operational cost—all while remaining easy to integrate into existing infrastructure. These solutions allow real-time updates on inventory and in/out transactions by connecting directly with plant systems.

Unified Equipment Scheduling and Interoperability

To function effectively, SMT assembly storage solutions must communicate seamlessly with placement machines and peripheral devices. This requires coordination through a unified scheduling platform, which ensures that various systems share data efficiently. PassionIOT enables this interoperability by deploying centralized control systems that align storage with production requirements. Collaboration with capable SMT equipment manufacturers is essential to ensure compatibility across different machine types.

Alignment Across the Production Line

Consistent performance depends on selecting SMT equipment manufacturers that support modular and scalable deployment. As SMT assembly storage solutions become more intelligent, equipment must keep pace by offering real-time data interfaces and operational transparency.

To conclude, efficiency no longer hinges on isolated performance but on synchronized function. When SMT assembly storage solutions and SMT equipment manufacturers operate in harmony, the result is not just production—it’s orchestration of precision and speed in motion.