In the rapidly evolving landscape of energy transmission, the resilience and efficiency of Ultra-High Voltage (UHV) grid systems are paramount. The demand for robust and innovative power solutions is on the rise, particularly for organizations operating under extreme conditions and continuous loading. This is where SH POWER stands out, providing specialized, comprehensive industrial power solutions that cater to the unique challenges facing modern power infrastructure.

Transformers: The Heart of UHV Systems

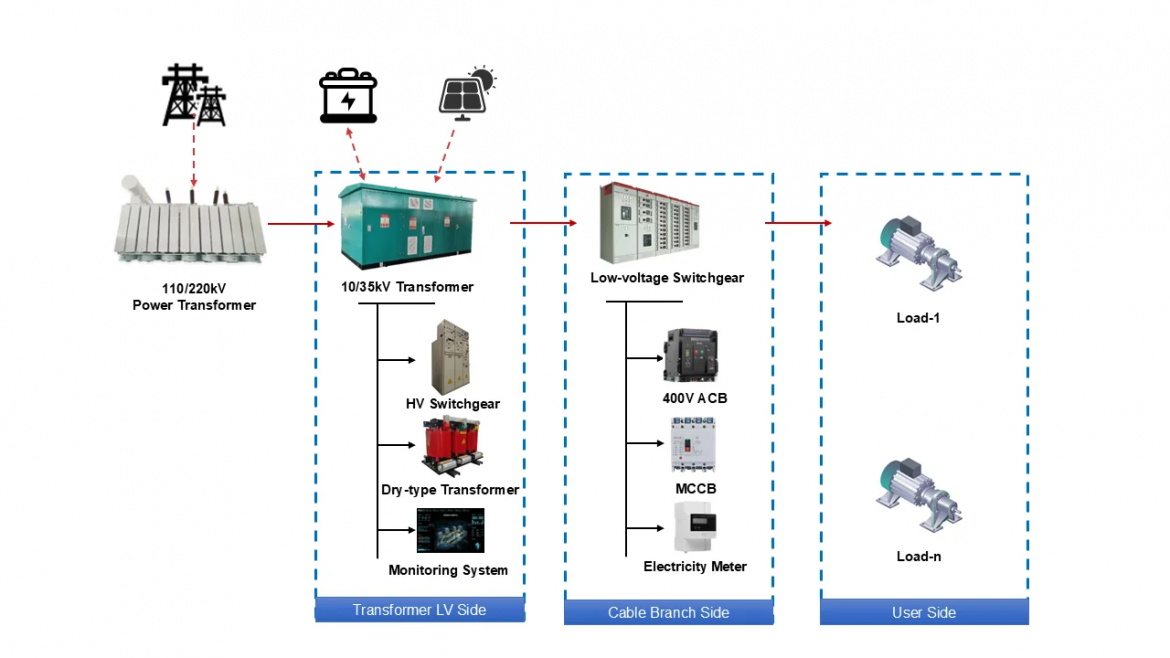

Transformers play a crucial role in UHV grid components, facilitating safe and efficient voltage transformations. SH POWER offers a range of heavy-duty transformers specifically designed for high-load environments, ensuring reliability and longevity. Their transformers are engineered to minimize energy loss, thereby enhancing overall network efficiency—an essential requirement for large-scale operations.

Low Voltage Panels: Optimizing Control

Effective control of power distribution is critical in preventing system failures in UHV grids. SH POWER provides custom industrial power solutions that include modular low-voltage panels designed for seamless operation in harsh industrial settings. These panels are capable of handling significant loads while effectively managing power flow, thus contributing to the stability of the entire grid system.

Reactive Compensation Solutions: Enhancing Power Quality

The importance of managing voltage fluctuations and reactive power in UHV systems cannot be overstated. SH POWER addresses these challenges through advanced reactive compensation technologies, ensuring that power quality remains uncompromised. By integrating these custom industrial power solutions, organizations can improve efficiency and reduce operational risks associated with fluctuating power demands.

Conclusion

In conclusion, navigating the complexities of UHV grid component design requires a deep understanding of both the challenges and the right power solutions. SH POWER emphasizes the importance of tailored strategies, combining cutting-edge transformers, low-voltage panels, and reactive compensation systems. By leveraging these innovative industrial power solutions, businesses can significantly enhance the performance and resilience of their power infrastructure, securing a reliable energy future.