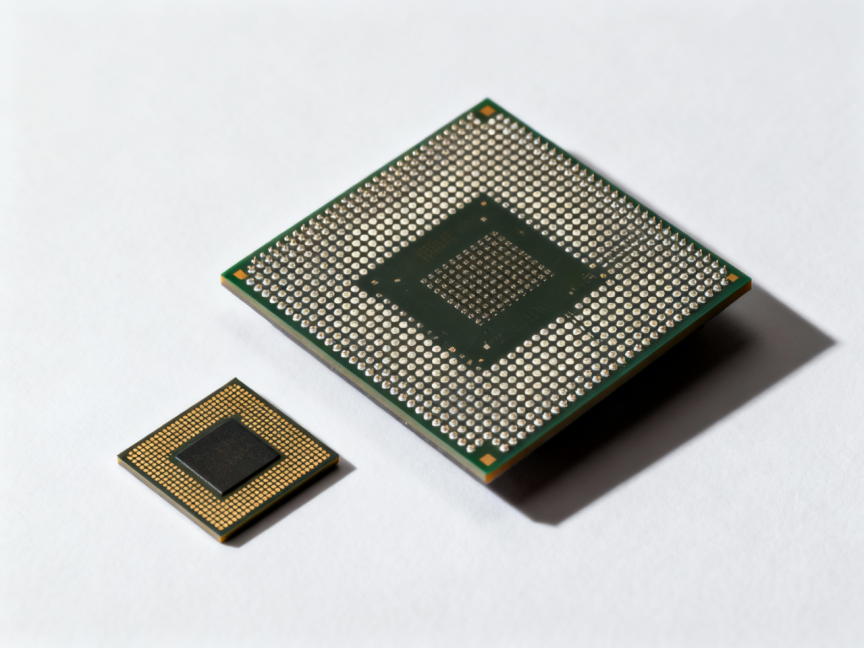

The transition from the previous memory standard to the latest generation represents the most significant architectural leap in a decade. For enterprise architects and data center managers, the fundamental difference between DDR4 and DDR5 is not merely a boost in frequency; it is a structural revolution defined by density scaling. While DDR4 is physically capped at a 16Gb memory die density, DDR5 architecture supports up to 64Gb dies. This critical shift allows for the production of massive capacity DIMMs—ranging from 128GB to 256GB and beyond on a single stick—overcoming the hardware bottlenecks that currently constrain AI training models and in-memory databases.

Die Density & Capacity: Breaking Physical Limits

The evolution of memory technology has moved beyond simple speed increments to address the physical limitations of capacity and power delivery. DDR5 introduces a complete redesign of the module architecture, enabling data centers to double or quadruple their memory density per rack unit without increasing the physical footprint.

The most consequential limitation of DDR4 technology is its maximum die density of 16Gb. To achieve high-capacity modules, such as 64GB or 128GB, manufacturers were forced to utilize complex and expensive Through-Silicon Via (TSV) stacking processes to combine multiple dies. DDR5 eliminates this constraint by natively supporting 64Gb dies.

This increase in density allows for the creation of 128GB, 256GB, and eventually 512GB DIMMs using standard packaging methods.For high-performance computing (HPC) environments, this means a single server can support terabytes of memory with fewer modules, optimizing space and power consumption for AI training, in-memory databases, and high-performance computing clusters.

Voltage Reduction and On-Module Power Management

Power efficiency is a critical differentiator in large-scale deployments. DDR4 relies on the motherboard to manage voltage regulation, which can lead to inefficiencies and signal noise as power travels across the board. DDR5 moves this function directly onto the module with an On-DIMM Power Management Integrated Circuit (PMIC).

Comparison of Power and Architecture:

By lowering the operating voltage from 1.2V to 1.1V and regulating it locally, DDR5 improves signal integrity and reduces power consumption at the system level. For enterprise servers running 24/7, this reduction in thermal output lowers cooling costs and enhances long-term component stability.

Operational Excellence: Reliability, Speed, and Future-Proofing

Beyond physical capacity, the difference between DDR4 and DDR5 ram lies in how they handle data integrity and throughput.

The limitations of DDR4 lie in the fact that ECC is optional and handled externally, making the chips susceptible to bit flips in high-density scenarios. To address this, every DDR5 chip will include on-chip ECC as a standard feature. DDR5 integrates ECC directly into each chip, automatically correcting single-bit errors before the data reaches the CPU. This complements traditional sideband ECC, creating a two-tiered defense.

Such reliable uptime is crucial for mission-critical systems (e.g., financial transactions, healthcare), where even minor errors can lead to costly downtime.

Performance: Bandwidth & Parallelism

DDR4 starts at a speed of 3200 MT/s, while DDR5 starts at 4800 MT/s and can scale up to 8400 MT/s. This high bandwidth is crucial for meeting the data transfer demands of modern multi-core processors.

DDR5 adopts a channel-splitting architecture, dividing the traditional 64-bit channel into two independent 32-bit sub-channels. This design effectively reduces channel idle time during data transmission, significantly improving parallel data access efficiency and laying the hardware foundation for high-performance data processing. Furthermore, DDR5 is specifically optimized for AI and high-performance computing (HPC) applications. Its faster data transfer speed fully meets the high-intensity computing demands of real-time data analysis, machine learning model training, and complex scientific simulations, enabling researchers and developers to gain critical insights from massive datasets more quickly and accelerate technological research and innovation.

UniBetter: Your Trusted Partner for Electronic Component Sourcing

As a world-leading electronic components distributor, UniBetter specializes in providing robust procurement solutions for enterprise and industrial clients. UniBetter understands that navigating the transition between memory generations requires a reliable supply chain that guarantees authenticity and availability.

Global Procurement with 100% Quality Assurance

UniBetter distributes a wide array of electronic components, leveraging a global UniBetter distributes a wide array of electronic components, leveraging a global network of over 7,000 trusted suppliers. Its commitment to quality is absolute; the company operates a CNAS-certified laboratory to ensure that every component it sources—whether the latest high-density memory or a hard-to-find legacy part—is 100% authentic and meets rigorous industrial standards. UniBetter’s proprietary CSD quality management system ensures that clients’ infrastructure is built on verified, reliable hardware.

Solving Shortages and Managing Obsolescence

In a volatile market, securing the right components at the right time is critical. UniBetter excels in shortage management, helping clients locate scarce electronic parts to keep production lines moving. Furthermore, its expertise in obsolescence management allows it to support long-lifecycle industrial systems that may still require legacy components. Whether clients are scaling up with the newest technology or maintaining critical existing infrastructure, UniBetter offers cost-effective, turnkey procurement services designed to streamline their supply chain and reduce operational risks. The company encourages clients to evaluate their infrastructure needs today; partnering with UniBetter enables businesses to access secure, efficient, and quality-assured electronic component procurement that empowers them to meet the demands of tomorrow.