As the China 3D Printing Expo 2026 approaches, industry professionals are eagerly preparing to explore the latest in additive manufacturing. TCT Asia has become a central platform for discovering innovations in metal 3D printing, offering insights that go beyond traditional manufacturing. With the Shanghai event scheduled for March 17-19, 2026, attendees will experience hands-on demonstrations and meet leading experts.

Advancements in Metal 3D Printing Manufacturers

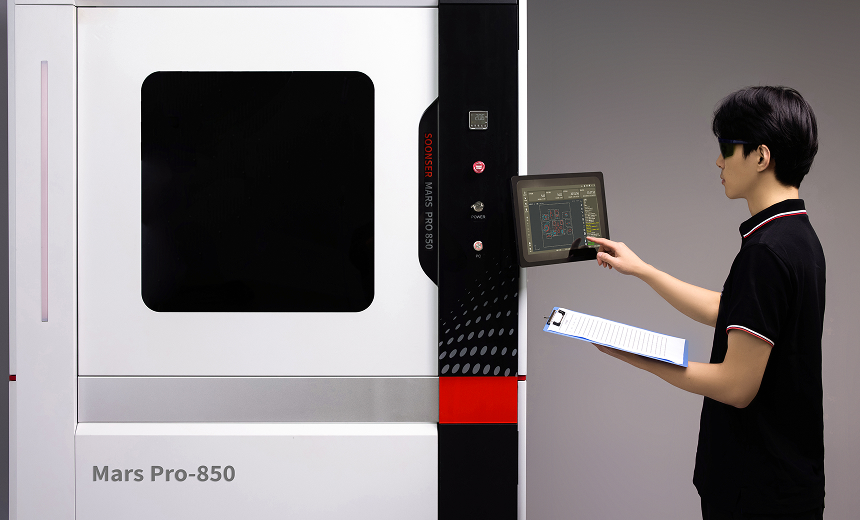

At TCT Asia, metal 3D printing manufacturers showcase technologies that are redefining production. They focus on improving precision, efficiency, and material versatility. Among the highlights is the Caterpillar mobile laser repair system, a tracked mobile laser repair system specifically designed for field maintenance operations in land combat. This system integrates laser powder cladding functionality, a powder feeder, and a load capacity of 15kg, demonstrating how additive manufacturing is expanding into highly specialized industrial applications.

Hands-On Demonstrations and TCT Asia Summit 2026

Visitors at TCT Asia summit 2026 will benefit from live demonstrations, which allow them to understand complex processes intuitively. Core components of advanced systems, such as lightweight robots, lasers, water cooling machines, integrated control systems, and self-propelled tracked vehicles, are presented in real operational scenarios. By engaging directly with these machines, engineers and designers gain practical insights that help optimize their workflows and explore new material capabilities.

Networking Opportunities and Industry Growth

TCT Asia not only highlights cutting-edge machinery but also fosters meaningful connections. Over 400 exhibitors and 25,000 visitors will attend the Shanghai show, providing opportunities to discuss collaboration with metal 3D printing manufacturers. As China’s additive manufacturing sector continues to grow, this expo serves as a valuable platform for knowledge exchange and business development, bridging the gap between design, engineering, and manufacturing.

Conclusion: Why TCT Asia 2026 is Unmissable

In summary, TCT Asia 2026 offers an unparalleled view of the evolving metal 3D printing landscape. From innovative metal 3D printing manufacturers to live demonstrations at the TCT Asia summit 2026, the event provides both educational value and business opportunities. Attending the Shanghai exhibition from March 17-19, 2026, ensures professionals remain informed about the latest technologies while exploring practical applications, making it a must-see event in the 3D printing calendar.