High levels of accuracy and efficiency are required in the dynamic field of automobile manufacturing. LEAD, a leader among smart manufacturing companies, is at the forefront with its innovative Five-axis High-speed Dispensing technology. This advanced solution offers high-speed and high-precision uniform dispensing for multi-complex surface structures, making it an indispensable tool for modern automotive manufacturing.

Enhanced Precision with Five-Axis Linkage

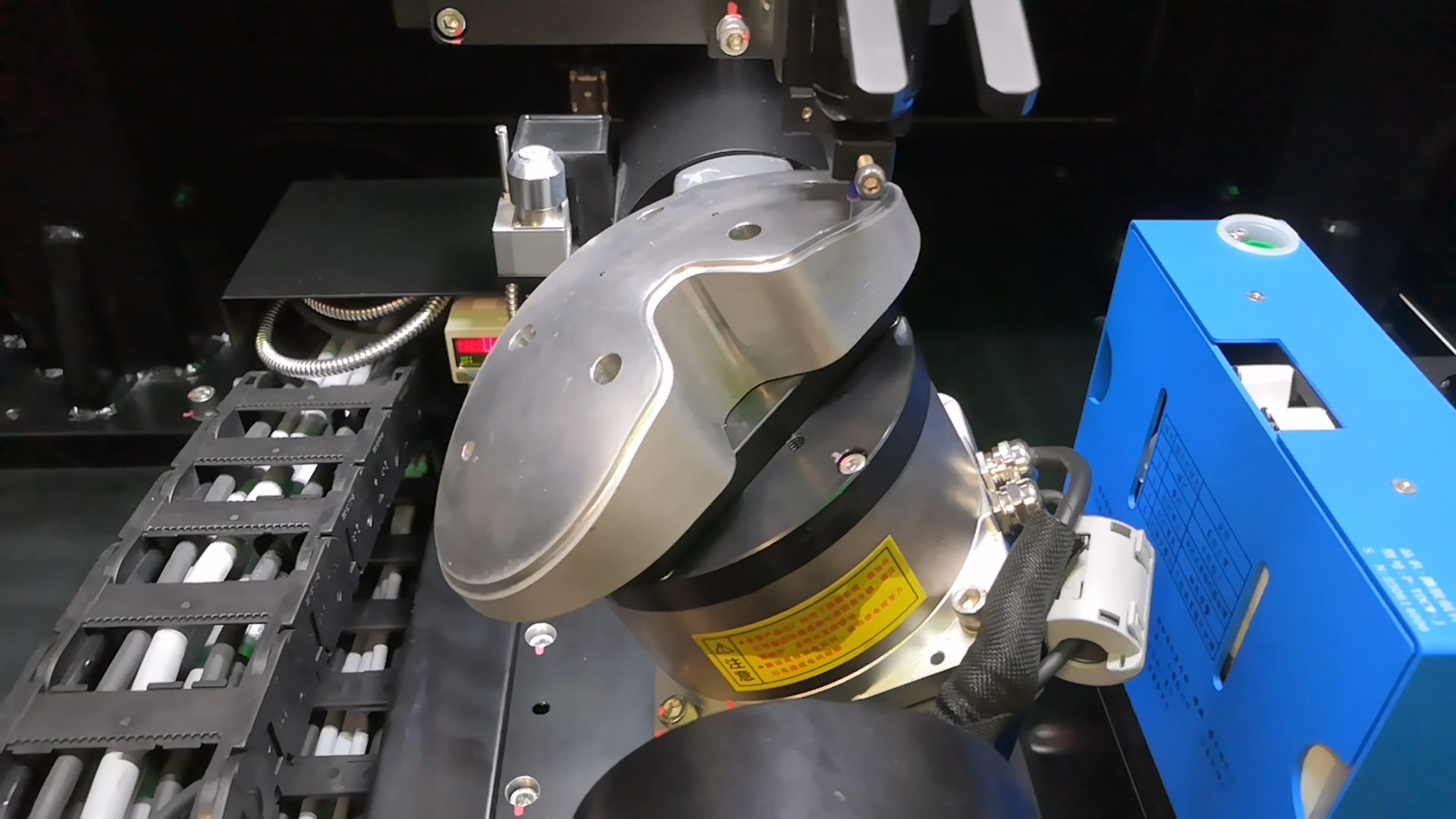

The Five-axis High-speed Dispensing system from LEAD utilizes a sophisticated five-axis linkage mechanism that ensures consistent and accurate application of adhesive materials. This technology is particularly beneficial for automotive production, where the complexity of components demands a high level of precision. By integrating a self-developed glue amount compensation algorithm, LEAD enhances the reliability of the dispensing process, minimizing waste and ensuring optimal material usage.

Comprehensive Solutions for Automotive Manufacturing

LEAD’s commitment to providing full solutions in automotive production sets it apart from other smart manufacturing companies. Their offerings include a complete automotive battery production solution, which encompasses battery cell production, packaging, and testing equipment. This all-in-one approach streamlines operations reduces production time, and enhances quality control, thereby meeting the rigorous demands of the automotive industry.

Conclusion

In summary, LEAD’s Five-axis High-speed Dispensing technology is a game-changer for automotive production, offering unmatched precision and efficiency. With a focus on comprehensive solutions and smart equipment, LEAD is dedicated to driving innovation in the automotive sector. As a leader among smart manufacturing companies, LEAD continues to pave the way for advanced manufacturing processes that meet the evolving needs of the industry.