Understanding the lifespan of heat shrink tubing is crucial for businesses in the medical device industry. Medical grade heat shrink tubing, in particular, plays a vital role in protecting sensitive components and ensuring the safety of devices used in healthcare settings. Knowing how long this tubing lasts can help manufacturers make informed decisions about their products.

Factors Influencing Durability

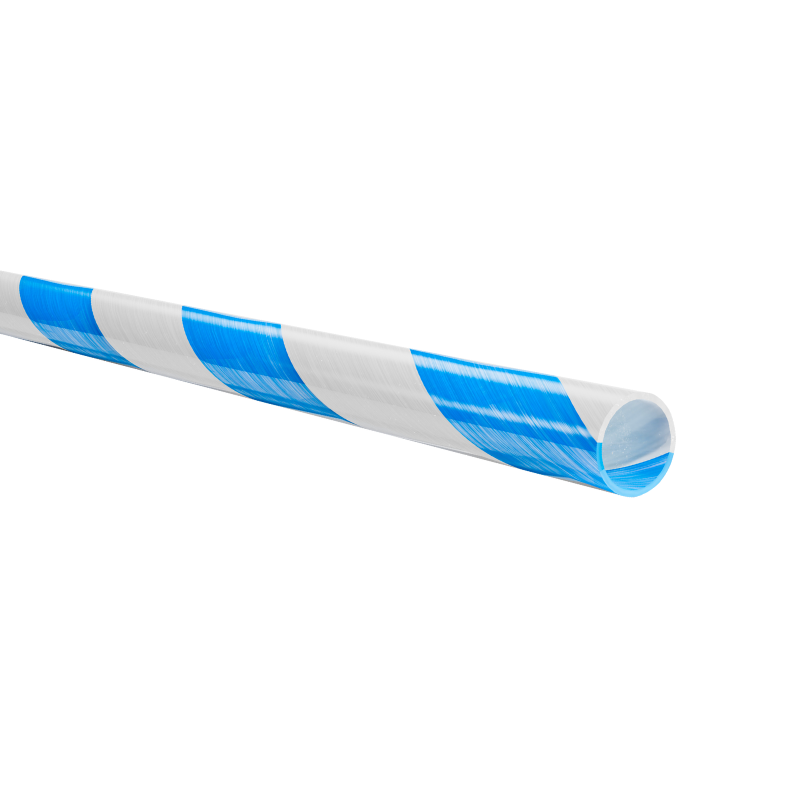

The longevity of medical grade heat shrink tubing depends on several factors, including the material composition, environmental conditions, and the specific application. High-quality materials, like the PTFE used in jMedtech’s Zebra Spiral Heat-Shrink Tubing, provide excellent resistance to chemicals, moisture, and extreme temperatures, significantly extending the product’s life. Additionally, proper installation and usage according to manufacturer guidelines can also enhance durability.

Applications in Medical Devices

Medical grade heat shrink tubing is widely used in various applications, particularly in minimally invasive procedures. It provides insulation and protection for delicate wires and components, ensuring reliability in critical medical devices. The striped visibility of jMedtech’s PTFE heat shrink tubing allows for easy identification during assembly and inspection, further contributing to its effectiveness in healthcare applications.

Maintenance and Replacement Considerations

While medical grade heat shrink tubing is designed for durability, regular inspection is essential. Factors such as exposure to harsh chemicals or extreme temperatures can affect its lifespan. Businesses should establish maintenance schedules to monitor the condition of the tubing and determine when replacements are necessary to ensure optimal performance in medical devices.

Ensuring Quality and Longevity in Your Products

Choosing high-quality medical grade heat shrink tubing is essential for enhancing the longevity and reliability of medical devices. By partnering with trusted manufacturers like jMedtech, businesses can ensure they are using the best materials available, ultimately leading to improved patient outcomes and device performance. Investing in quality tubing is not just a choice; it’s a necessity for success in the competitive medical industry.