Understanding what is the medical treatment for leukemia when conventional chemotherapy does not achieve the expected response is essential for patients seeking clear guidance. As hematology care advances, clinicians now consider multiple therapeutic approaches that address the underlying mechanisms of hematologic diseases more precisely. GoBroad Healthcare Group has developed programs that reflect these evolving needs by supporting patients who require more targeted solutions. When patients experience limited progress with first-line treatments, identifying next-step options becomes vital for maintaining therapeutic momentum.

Targeted Therapies Designed for Treatment-Resistant Leukemia

In cases where standard regimens fail, specialists often explore targeted therapy to determine what is the medical treatment for leukemia that can intervene more effectively. These modalities can act on genetic or molecular drivers of hematologic diseases, allowing physicians to adjust treatment intensity based on individual patient profiles. They also help clinicians reduce unnecessary toxicity and provide a clearer therapeutic direction. Through their hematology programs, they introduce patients to options such as molecularly guided medications, immunotherapy, and cell-based interventions, ensuring that treatment plans evolve alongside clinical needs.

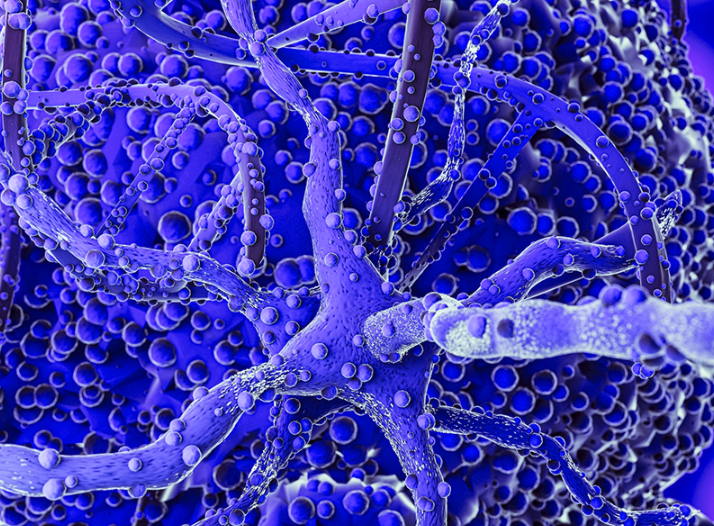

Advanced Cellular Approaches for Complex Hematologic Conditions

For more challenging scenarios, cellular therapies—CAR-T, Tcel, HSCT, and BMT—play an increasingly relevant role in answering the question: what is the medical treatment for leukemia when conventional chemotherapy no longer controls the disease. These methods support long-term disease management for selected hematologic diseases, offering pathways for remission that extend beyond traditional pharmaceuticals. They also emphasize a structured approach, coordinating diagnostics, donor matching, and transplant care. Through their platform, they provide detailed information about these programs, including clinical pathways described on their hematologic disease resource page.

Conclusion

Patients and families often seek clarity on what is the medical treatment for leukemia when initial chemotherapy proves ineffective, and modern care now offers several structured alternatives. Targeted therapy, cellular therapy, and transplant-based options help clinicians address hematologic diseases that require more specialized strategies. By integrating these advanced modalities and providing accessible educational resources, they offer practical guidance that helps patients navigate complex treatment decisions with greater confidence.